Rainstorm is a National Distributor of the STEMGEL™ range of hydrogel stemming products by Shockwave Gel Technologies.

Shockwave’s range of unique stemming products and custom-designed application equipment bring new and advanced technology to the entire drill and blast industry across the mining, civil, military and other sectors. Each product in the range is designed and manufactured in Western Australia to bring improved performance and control, cost reductions, dust reductions and increased safety to drill and blast applications across the world.

STEMGEL™ is a unique formula comprising a concentrated liquid reagent and specialty polymer blend. When it is added to water, STEMGEL™ inverts to form a solid hydrogel with a large attenuation coefficient.

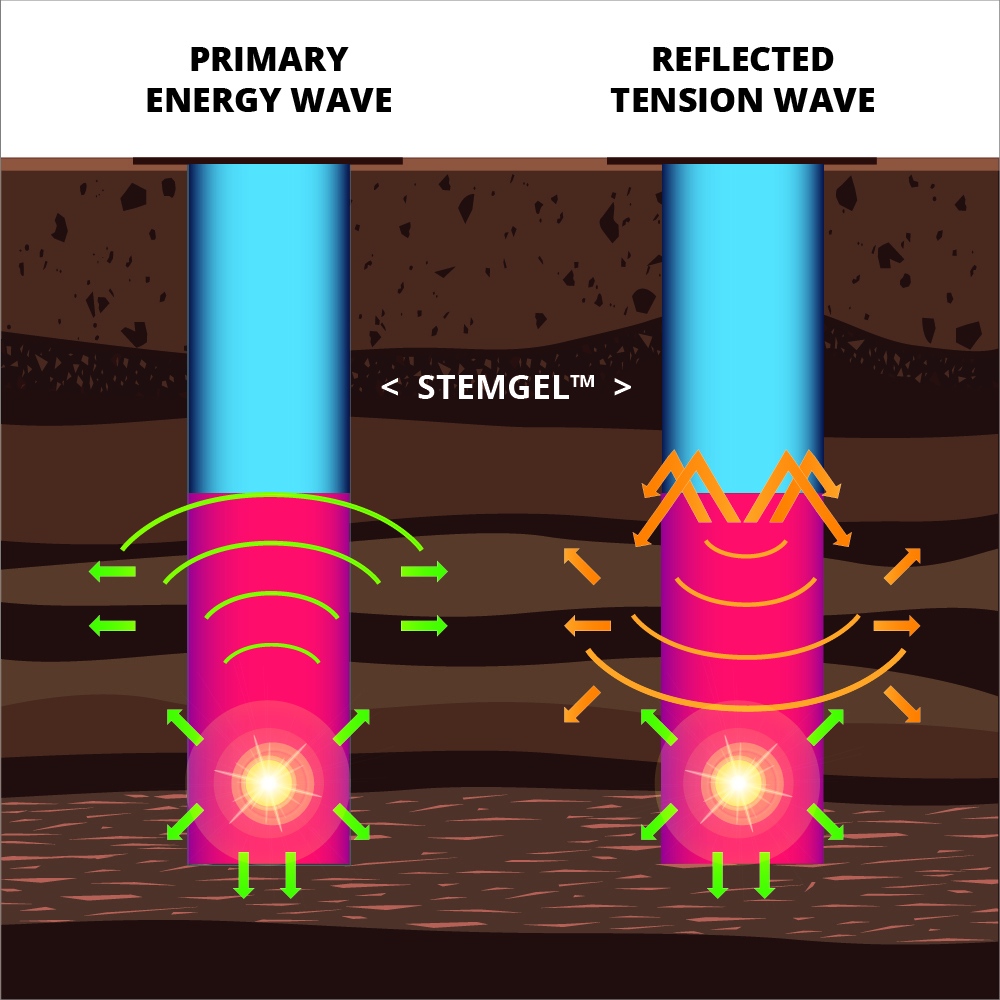

STEMGEL™ is loaded easily and efficiently, hose in hose with water, into the blast hole using powered dose pump applicators. Set in place as a stem deck coupled to the explosive compound, the STEMGEL™ deck attenuates the pressure shockwave upon initiation of the blast.

The energy is compressed and reflected back into the formation, minimising energy loss and increasing rock fragmentation. Gas expression is increased within the rock layers and STEMGEL™ is ejected as water vapour with lower air overpressure, noise and significantly improved blast dust control.

Focus on Safety and the Environment

The entire range of Shockwave stemming products is eco-friendly, non-toxic and safe for both operators and the natural environment in which they are used.

Our specialised dosing equipment is designed to make use of our products fast and simple in all applications and our automated dosing machinery can limit or even eliminate the need for personnel on the blast floor.

Advantages of stemming with STEMGEL™

- Improved safety on the blast bench

- Substantially more effective rock breakage and micro-fracturing

- Reduction in oversize material

- Fast and simple loading

- Reduced noise and fumes

- Protection of detonation cord and easy misfire fixing

- Compatibility with all explosives

- Effective blast dust control in both open-cut and underground drilling situations

- Effective solution to hole water issues

- Non-toxic and environmentally safe

Challenges solved by STEMGEL™

- Poor blast dust control

- Inconsistent stemming

- High dust, noise and fume emissions

- Ineffective and unsafe underground stemming

- Poor fragmentation

- Downhole water

Multiple Solutions In One

STEMGEL™ LRC

Open cut stemming solution.

An easy and safe-to-load concentrated liquid reagent with multiple applications for down-hole and above-hole stemming in open-cut mines and civil industries. Able to completely replace aggregate stem, STEMGEL™ LRC generates a consistently controlled and superior blast result in a short time period, at a lower cost and with numerous operational efficiencies. View the STEMGEL™ data sheet left for more information.

STEMGEL™ SUB T

Underground stemming solution.

An easy and safe-to-load concentrated liquid reagent that brings unprecedented control to horizontal and vertical up-hole blasting underground.

Effective for both production and pre-stress blasting, STEMGEL™ SUB T is a game-changer for underground blast activities, effectiveness and most importantly, safety. View the SUB T data sheet left for more information.

DHDA™ Down Hole Dewatering Agent

Open cut wet and hot hole solution.

DHDA™ is an easy and safe, manually loaded concentrated granular reagent that effectively and instantly reacts with downhole water to form a dense gel stemming deck, ensuring the hole is ready and safe to load with blasting materials. View the DHDA™ data sheet left for more information.

BLASTMATT™

Pre-Packaged STEMGEL™ Mat

The BLASTMATT™ is a 250m x 40mm panel that can be cut to size for each application. The mat is pre-filled with STEMGEL™ concentrate and activated by adding water to form a portable, stabilised hydrogel stemming pad.

Designed for use in open-air rock breaking and ideal for dampening air blast and fly rock, as well as multiple military applications.

STEMGEL™ Actions

STEMGEL™ reflects or attenuates 98% of the pressure wave (Pw) generated by the detonation of explosives. The Pw is reflected into the most ridged surface i.e. surrounding rock, to increase shattering during the initial moments of explosion.

The explosive energy can be enhanced by the more controlled containment of expanding gases. STEMGEL™ density can be adjusted to increase the total mass by manipulating the addition of dissolved and/or undissolved solids. This can further increase blasting performance.

Get In Touch

Water on Dust Control is Water Lost. Tell us your dust problem and we'll tailor a sustainable solution.